Fascination About Mhs - Material Handling Supply Inc.

Fascination About Mhs - Material Handling Supply Inc.

Blog Article

Mhs - Material Handling Supply Inc. Things To Know Before You Get This

Table of ContentsExcitement About Mhs - Material Handling Supply Inc.The smart Trick of Mhs - Material Handling Supply Inc. That Nobody is DiscussingThe Best Guide To Mhs - Material Handling Supply Inc.Everything about Mhs - Material Handling Supply Inc.Indicators on Mhs - Material Handling Supply Inc. You Should KnowThe Ultimate Guide To Mhs - Material Handling Supply Inc.Examine This Report on Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. for Beginners

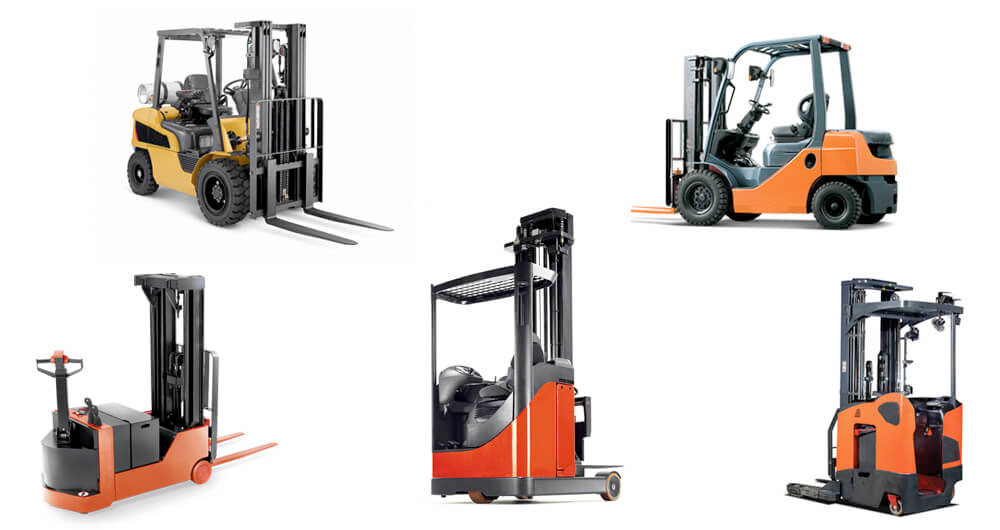

Rather, they are used to increase loads simply sufficient to permit horizontal activity. There are two various types of forklift vehicles in this team: straight-mast and extended-reach.Powered by diesel, RTFLs supply a safe means to travel with tons on uneven ground. These forklifts are utilized for moving and stacking ISO typical containers for the delivery market. They can lift up to 60 lots at low rates. This is the very same as two complete containers. Straddle vehicles can stack containers greater than 13 ft.

Motorists sit at the top of the truck so they can see in front and behind them. These trucks also are available in mini versions to move containers around backyards and depots. These forklifts are made use of to take care of lumber, steel bars, pipelines, and other long products. Unlike other forklifts, they do not have front uprights that can obstruct of packing and dumping.

The 4-Minute Rule for Mhs - Material Handling Supply Inc.

They are set up onto vehicles to enhance the loading and discharging procedure. The majority of forklifts have a three-point suspension system that consists of two front wheels and a pivot point at the rear axle. Together, these points create a "security triangular" that lessens the risk that a lift will certainly topple, even on high or sturdy surface.

In this instance, the forklift's center of gravity falls outside the stability triangle. A forklift's facility of gravity moves any kind of time a lift driver accelerates, brakes, or turns.

How Mhs - Material Handling Supply Inc. can Save You Time, Stress, and Money.

Comprehending what are the various types of forklifts is just the beginning. Prior to you can operate any forklift, you have to be correctly educated to do so. Producers procedure and test forklifts and assign these specifications to shield drivers from mishaps and rollovers.

Excitement About Mhs - Material Handling Supply Inc.

In the United States, Occupational Security and Health Administration (OSHA) regulates the use of powered forklifts and requireds operators must be at the very least 18 years old. Most forklifts have a power resource to do the heavy lifting and maneuvering.

Propane prevails, affordable and burns clean. LPG forklifts can be utilized indoors due to the fact that they operate silently and do not launch high quantities of unsafe discharges. LPG containers are typically installed on the rear of the truck and are designed to enable fast altering. Diesel: Diesel forklifts offer more power and lift ability than LP forklifts, and they are better matched for exterior applications since diesel exhausts require continuous air flow.

Excitement About Mhs - Material Handling Supply Inc.

Harsh terrain forklifts are designed for outdoor usage on unequal surface areas - forklift dealer watkinsville, ga. Some rough terrain forklifts have stabilizers to offer extra stability support.

An Unbiased View of Mhs - Material Handling Supply Inc.

Pallet jacks are the easiest and many fundamental forklift style including 2 forks generally 20 1/4 inches or 27 inches wide. Their basic function is limited to moving pallets inside a warehouse. Pallet jacks usually have steering wheels in the front, and each fork has either a solitary wheel or 2 bogie wheels.

The majority of pallet jacks are made to handle about 5,000 pounds usually, and some designs have the ability to lift up to 8,000 lbs. There are 3 common types of pallet jacks: Manual pallet jacks are hand-powered by the driver and used to raise, reduced, and guide pallets from one place to an additional.

Little Known Facts About Mhs - Material Handling Supply Inc..

They are generally utilized in retail and warehousing procedures - forklift dealer watkinsville, ga. Powered pallet jacks (additionally recognized as electrical pallet trucks walkies and power jacks) are comparable to hand-operated pallet jacks in layout, nevertheless, they include an engine that enables lifting and moving of much heavier and piled pallets. Some powered pallet jacks include a platform for the driver to stand upon while using it

They feature sturdy frameworks and pneumatically-driven tires to fit a wider variety of surface area types. Walkie stackers are one more straightforward layout including a mast that allows lifting hauls to greater heights than pallet jacks. Walkie stackers are typically said to be a combination of a pallet jack and forklift - due to the fact that they have a straightforward layout and handle (similar to a pallet jack) while supplying reach (similar to a forklift).

Operators usually overview his comment is here and navigate the walkie stacker around the storage facility by pulling the take care of. The majority of walkie stackers are designed to deal with between 2,000 and 3,000 lbs typically, with some versions raising to 4,000 lbs (Forklift dealer athens, ga). Lift elevations differ based upon make and version and usually range in between 6 and 14 feet

Not known Facts About Mhs - Material Handling Supply Inc.

Report this page